Our Solutions

CLICK ON THE SOLUTION THAT INTERESTS YOU

Menu

Menu

DEVELOPMENT AND INNOVATION OF

Equipment for the Battery Industry

CEDINSA® develops, designs, and manufactures equipment with the highest quality standards to maintain controlled environments within battery installations.

TURNKEY

Project

We offer solutions to various industries such as automotive, electric vehicle battery installation, textile, and pharmaceutical. We specialize in high-quality, strictly controlled temperature and humidity conditions for ultra-clean environments:

Solutions:

- Air Supply Houses

- Recirculation Filter Houses

- Over Heater Boxes

- Cooling Units

- Filters Houses

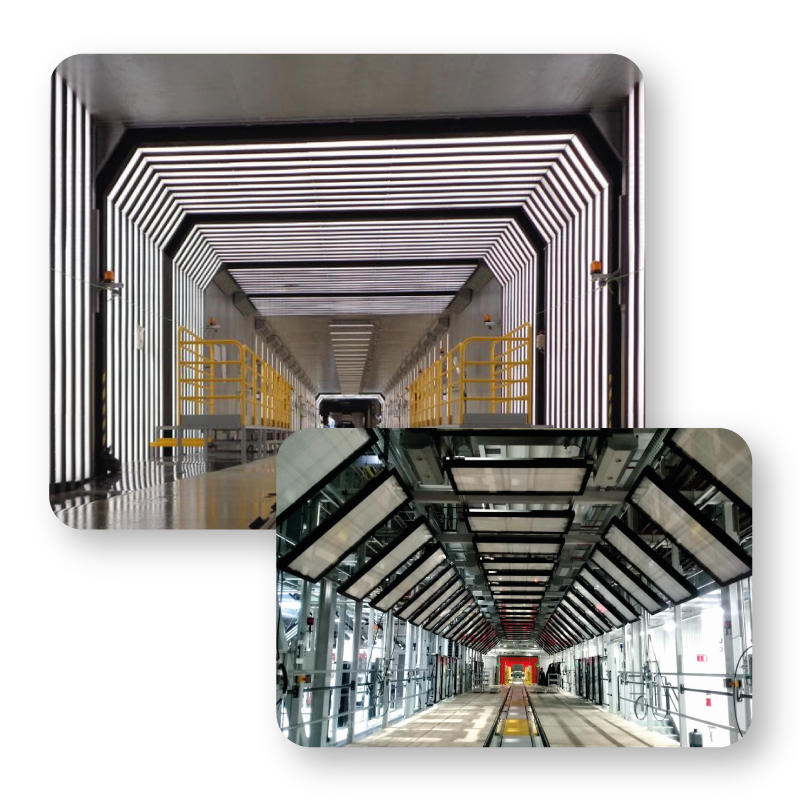

- Spray Booths

- Batch & Continuous Ovens

- SMACNA Certified Ductwork

- Cleanrooms

- PT/EC Enclosures

- Air Shower / Air Locks

- Work Decks

- BCU (By-Pass Cooling Units)

- DOA with Energy Recovery

- Textile Mills Solutions

- Pharmaceuticals Machine

SERVICE

Engineering and CFD Simulation

Our team of engineers has the capability and experience to generate precise calculations, which allows us to select and design equipment that meets our clients' needs within their processes.

CEDINSA® offers its clients the ability to visualize the behavior of their processes before modifying them and/or manufacturing the necessary equipment, through CFD modeling, thus providing a tangible confirmation of the previously calculated results.

CEDINSA® offers its clients the ability to visualize the behavior of their processes before modifying them and/or manufacturing the necessary equipment, through CFD modeling, thus providing a tangible confirmation of the previously calculated results.

SERVICE

Maintenance

At CEDINSA®, we have an AFTER-SALES service department that will help you schedule preventive and corrective maintenance services for your installations, as well as the supply of proprietary consumables.

Experience peace of mind with our personalized HVAC service programs, ranging from semi-annual maintenance visits to fully managed operations. We go beyond equipment manufacturing, ensuring optimal performance, periodic inspections, and providing KPIs to improve efficiency.

We currently have annual contracts established with companies like COMPAS, in which we are responsible for:

Experience peace of mind with our personalized HVAC service programs, ranging from semi-annual maintenance visits to fully managed operations. We go beyond equipment manufacturing, ensuring optimal performance, periodic inspections, and providing KPIs to improve efficiency.

We currently have annual contracts established with companies like COMPAS, in which we are responsible for:

- More than 5,000 air conditioning units.

- Management of sludge pits.

- Cleaning of paint booths.

- Supply, control, and replacement of filters in AHUs, booths, ovens, and combustion chambers.

- Balancing of paint booths.

Service

Design

Service

Installation and Assembly

We have trained personnel to carry out the field installation of HVAC-H products: H for heating, V for ventilating, AC for air conditioning, and alternate ventilation systems.

- Spare parts

- CEDINSA® 's after-sales service is always available with emergency visits and spare parts. Just a phone call away. (+52) 222 235 1001/1002

CEDINSA® keeps a record of the equipment installed in each of our projects to facilitate the identification of required parts. Additionally, we offer spare parts on demand in the following areas:

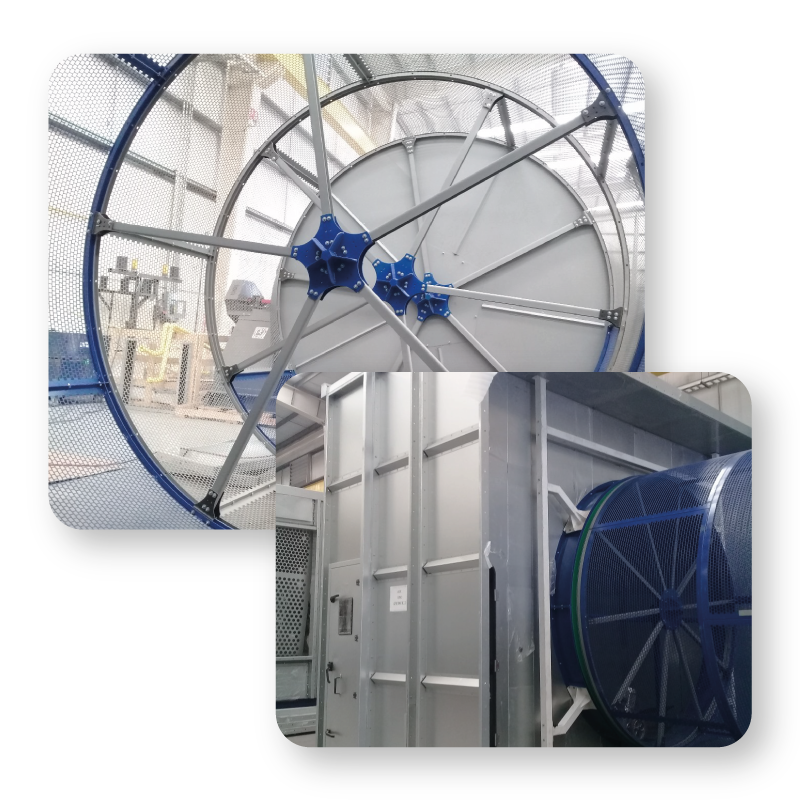

Textile

- For rotary filters: plush-type filter, rubber wheel, cleaning nozzle, and cleaning bag.

- Bag filter for inertial separator and zig-zag static mat filter.

- Sprays and spray holder tubes, pumps, polycord belt.

- Drop separators: stainless steel (3 bent, 5 bent), PVC (3 bent).

- Pneumatic diverter valve in various sizes.

Automotive

- Sprays, doors, dampers.

- Handles and sight glasses for doors.

- Drop separators: stainless steel (3 bent, 5 bent), PVC (3 bent).

- Inspection dampers and trapezoidal diffusers.

- Products

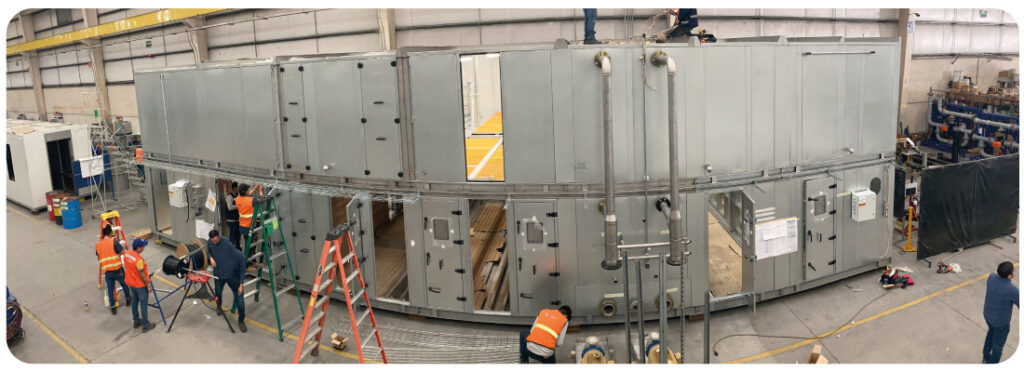

CEDINSA® is able to design and manufacture equipment on the basis of the specification of the customer to comply with the requirements of the process, in our workshop with more than 5,000 m2 production and area of assembly has machinery and skilled human capital for the development of these teams, as an example we can supply:

- Units Manejadoras Air (CPA, UMA, UPA)

- Control of humidity, temperature, filtration, and air pressure.

- Capacity to manufacture with higher throughputs to 350,000 m3/h

- Approved in companies such as NISSAN, AUDI, and GM

- Combustion chambers

- Curing ovens for paint lines

- Paint booths

- Cabins cooling

- Cabins test rains

- Ovens for vertical drying adhesive

- Cabins adhesive application

- System duct

- TOC

- Seam welder

- Bridado

- Soldier

- Espiroducto

- Material galvanized, aluminized, Phone and stainless.

- Tunnels of pretreatment